Carbon Steel Alloy Steel Plate

1. E sebelisoa e le tšepe bakeng sa likarolo tse sa tšoaneng tsa mochine.E kenyelletsa tšepe ea carburized, quenched and tempered steel, spring steel le rolling bearing steel.

2. Tšepe e sebelisoang e le mohaho oa boenjiniere.E kenyelletsa A, B, tšepe e khethehileng ea sehlopha le tšepe e tloaelehileng ea alloy ka tšepe ea carbon.

Tšepe ea sebopeho sa carbon

Ho sebelisoa lipoleiti tsa tšepe tse tšesaane tse tšesaane tsa boleng bo holimo tsa khabone le likhoele tse tšesaane li sebelisoa indastering ea likoloi, ea sefofane le makaleng a mang.Limaraka tsa eona tsa tšepe ke tšepe e nang le rimmed: 08F, 10F, 15F;tšepe e bolailoeng: 08, 08AL, 10, 15, 20, 25, 30, 35, 40, 45, 50. Lipoleiti tsa tšepe tse tlaase tsa carbon tse ka tlase ho 25 le 25, 30 le Ka holimo ho 30 ke poleiti ea tšepe ea carbon e mahareng.

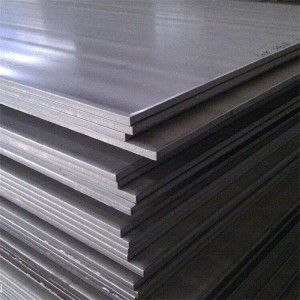

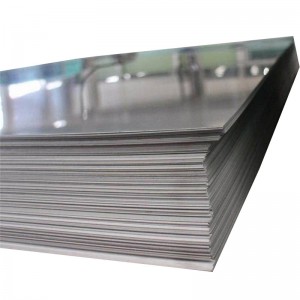

Tlhophiso ka botenya

Letlapa le tšesaane la tšepe <4 limilimithara (limilimithara tse tšesaane ka ho fetesisa 0.2), poleiti e teteaneng ea tšepe 4-60 limilimithara, poleiti ea tšepe e tenya e 60-115 mm.Bophara ba poleiti e tšesaane ke 500-1500 mm;bophara ba poleiti e teteaneng ke 600-3000 mm.Mofuta oa tšepe oa tšepe e teteaneng Ha e le hantle e tšoana le tšepe e tšesaane.Mabapi le lihlahisoa, ntle le lipoleiti tsa tšepe tsa borokho, lipoleiti tsa tšepe tsa boiler, lipoleiti tsa tšepe tse etsang likoloi, lipoleiti tsa tšepe tsa sekepe sa khatello le lipoleiti tsa tšepe tse nang le likhatello tse ngata, tseo e leng lipoleiti tse teteaneng, mefuta e meng ea lipoleiti tsa tšepe joalo ka koloi. lipoleiti tsa tšepe tsa tšepe (botenya ba 2.5-10 mm), mohlala Lipoleiti tsa tšepe (botenya ba 2.5-8 mm), lipoleiti tsa tšepe tse se nang mocheso, lipoleiti tsa tšepe tse sa keneleng mocheso, joalo-joalo li tšeloa ka lipoleiti tse tšesaane.2. Letlapa la tšepe le arotsoe ka mocheso o chesang le o batang ho ea ka ho roala.

E arotsoe ka sepheo

(1) Bridge steel plate (2) Boiler steel plate (3) Shipbuilding steel plate (4) Armor steel plate (5) Automobile steel plate (6) Roof steel plate (7) Structural steel plate (8) Electrical steel plate (silicon) letlapa la tšepe) (9) Letlapa la tšepe la selemo ( 10) Tse ling

E arotsoe ka sebopeho

1. Letlapa la tšepe bakeng sa sekepe sa khatello: Sebelisa capital R ho bontša qetellong ea kereiti.Mophato o ka hlahiswa ka ntlha ya chai kapa dikahare tsa khabone kapa likarolo tsa alloying.Joalo ka: Q345R, Q345 ke ntlha ea lihlahisoa.Mohlala o mong: 20R, 16MnR, 15MnVR, 15MnVNR, 8MnMoNbR, MnNiMoNbR, 15CrMoR, joalo-joalo kaofela li emeloa ke carbon content kapa alloying elements.

2. Letlapa la tšepe bakeng sa li-cylinders tsa khase ea welding: Sebelisa capital HP ho bontša qetellong ea sehlopha, 'me kereiti ea eona e ka hlalosoa ka ntlha ea lihlahisoa, tse kang: Q295HP, Q345HP;e ka boela ea hlahisoa ka likarolo tsa motsoako, tse kang: 16MnREHP.

3. Letlapa la tšepe bakeng sa boiler: Sebelisa litlhaku tse nyane g ho bontša qetellong ea lebitso la mochini.Kereiti ea eona e ka hlahisoa ka ntlha ea lihlahisoa, joalo ka: Q390g;e ka boela ea hlahisoa ke lihlahisoa tsa carbon kapa metsoako ea motsoako, joalo ka 20g, 22Mng, 15CrMog, 16Mng, 19Mng, 13MnNiCrMoNbg, 12Cr1MoVg, joalo-joalo.

4. Lipoleiti tsa tšepe bakeng sa marokho: Sebelisa litlhaku tse tlaase q ho bontša qetellong ea kereiti, joalo ka Q420q, 16Mnq, 14MnNbq, joalo-joalo.

5. Letlapa la tšepe bakeng sa beam ea koloi: Sebelisa capital L ho bontša qetellong ea kereiti, joalo ka 09MnREL, 06TiL, 08TiL, 10TiL, 09SiVL, 16MnL, 16MnREL, joalo-joalo.

(1) Cold rolled non-oriented silicon steel strip (sheet): Mokhoa oa boemeli: DW + boleng ba tahlehelo ea tšepe (ka makhetlo a 50HZ, boleng ba tlhōrō ea ho kenngoa ha makenete ka sinusoidal waveform ke tahlehelo ea tšepe ea 1.5T ka boima ba yuniti.) Linako tse 100 + boleng ba botenya makhetlo a 100.

Ka mohlala, DW470-50 e emela tšepe ea silicon e pota-potiloeng ke serame e nang le boleng ba tahlehelo ea tšepe ea 4.7w / kg le botenya ba 0.5mm.Mofuta o mocha o emeloa e le 50W470.

(2) Cold-rolled oriented silicon steel strip (sheet): Mokhoa oa boemeli: DQ + boleng ba tahlehelo ea tšepe (ka makhetlo a 50HZ, tlhōrō ea tlhōrō ea ho kenngoa ha makenete ka sinusoidal waveform ke 1.7T tahlehelo ea tšepe ka boima ba yuniti.) 100 linako + boleng ba botenya makhetlo a 100.Ka linako tse ling G e eketsoa ka mor'a boleng ba tahlehelo ea tšepe ho bontša induction e phahameng ea makenete.Ka mohlala, DQ133-30 e emela lesela la tšepe la silicon le nang le serame (letlapa) le nang le boleng ba tahlehelo ea tšepe ea 1.33 le botenya ba 0.3mm.Mofuta o mocha o se o emetsoe e le 30Q133.

(3) Letlapa la tšepe la silicon le chesang le chesang: Letlapa la tšepe la silicon le chesang le emeloa ke DR, le arotsoeng ka tšepe e tlaase ea silicon (litekanyo tsa silicon ≤2.8%) le tšepe e phahameng ea silicon (likahare tsa silicon> 2.8%) ho ea ka silicon. dikahare.Mokhoa oa boemeli: boleng ba tahlehelo ea tšepe ea DR + (boleng ba tahlehelo ea tšepe ka boima ba yuniti ha boleng bo phahameng ba ho kenngoa ha makenete ka 50HZ ho pheta-pheta magnetization le phetoho ea sinusoidal ke 1.5T) + makhetlo a 100 boleng ba botenya.Ka mohlala, DR510-50 e emela letlapa la tšepe ea silicon e chesang e chesang e nang le boleng ba tahlehelo ea tšepe ea 5.1 le botenya ba 0.5mm.Litekanyetso tsa lishiti tsa tšepe tsa silicon tse chesitsoeng bakeng sa lisebelisoa tsa ntlo li hlahisoa ke JDR + boleng ba tahlehelo ea tšepe + boleng ba botenya, joalo ka JDR540-50.

| Lebitso la Sehlahiswa | Plate ea tšepe ea Carbon |

| Mocheso o Phahameng oa Carbon Steel Plate | Mocheso o Phahameng oa Carbon Steel Plate |

| Sepheo se Ikgethileng | Plate ea Tšepe e Matla a Phahameng |