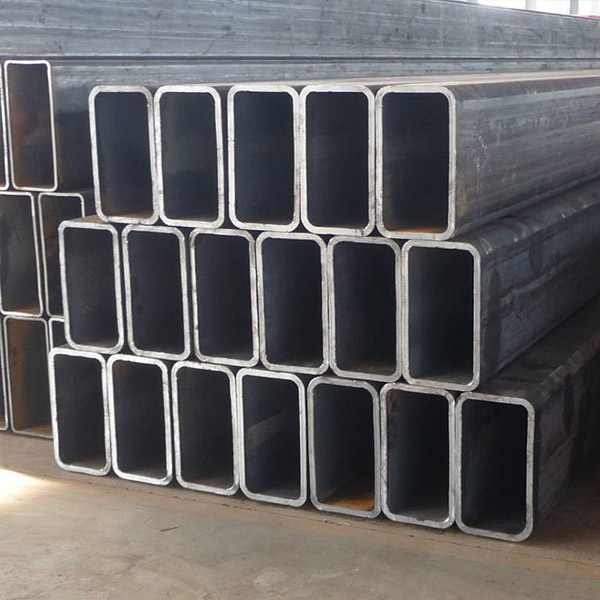

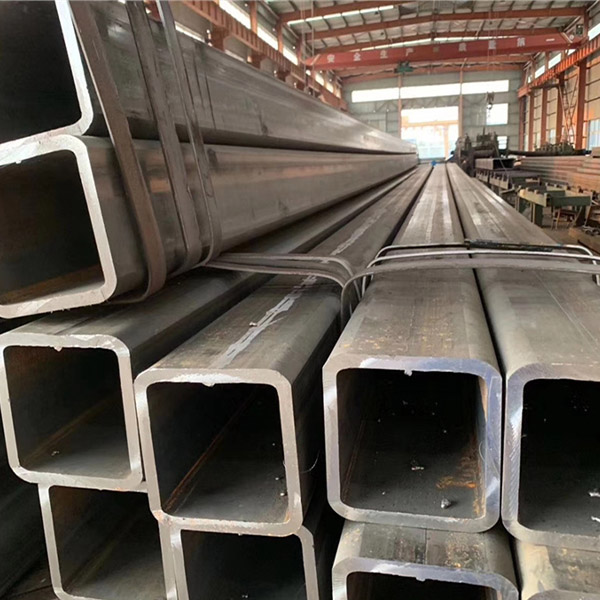

Welded Square Tube

e entsoe chaena

Sesebelisoa: tube ea boiler,

Hore na pipeline e hokahane le alloy: non-alloy

Sebopeho sa karolo: sekwere

Tube e khethehileng: API

Botenya ba tube: 1.5-60

Phekolo ea sefahleho: pente e ntšo

Mamello: ± 1%

Litšebeletso tsa ho lokisa: ho kobeha, ho cheselletsa, ho phunya, ho itšeha

lintho tse bonahalang: Q195/Q215/Q235/Q345/10#/20#

Bokaholimo: pente e ntšo ea spray

Sebopeho: square tube

Ho phuthela: ho phuthela ho tloaelehileng

Mantsoe a bohlokoa: phala ea tšepe e se nang seam

Nako ea ho fana: matsatsi a 7-15

Pipe ea tšepe ea sebopeho se ka hare: karolo e ntšo e sekoti

Bonyane palo ea odara: 1 ton

Morero: Mohaho oa mohaho

Theknoloji: Hot Rolling

Netefatso: API

1. Welded square tube ke sekoti se sekoere karolo ea tšepe ea square tube, e tsejoang hape e le tšepe e sekoti e entsoeng ka serame. E entsoe ka ho kobeha ho batang le ho cheselletsa maqhubu a phahameng ka mor'a hore ho be le khoele e chesang kapa e batang e phuthoang e le tšepe e se nang letho e nang le sebopeho le boholo ba lisekoere.

Ho phaella ho thickening lerako botenya ba teteaneng-mabota lisekoere tube, boholo sekhutlo le bohale flatness fihla kapa feta boemo ba ho hanyetsa welded batang thehoa lisekoere tube. Boholo ba angle ea R hangata bo pakeng tsa makhetlo a 2 le makhetlo a 3 ho feta botenya ba lebota. .Ho latela litlhoko tsa bareki, re ka boela ra hlahisa li-square tubes tsa R-angle tsa boholo bo hlokoang ke bareki;

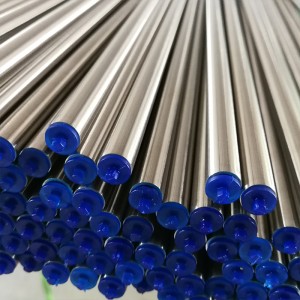

2. Square tube seamless square tube ke lesela le lelelele la tšepe le nang le karolo e sekoti 'me ha le na manonyeletso periphery. Ke tube ea lisekoere e entsoeng ka ho ntša tube e se nang seam ka mahlakoreng a 4 a hlobo. Sekwere tube e na le karolo e sekoti 'me e sebelisoa ka bongata. E sebelisoa ho lipalangoang tsa metsi, ts'ehetso ea hydraulic, sebopeho sa mochini, khatello e mahareng le e tlase, tube ea boiler ea khatello e phahameng, tube ea phapanyetsano ea mocheso, khase, peterole le liindasteri tse ling. E matla ho feta welded mme e ke ke ea peperana.

1. Ts'ebetso ea phallo ea tube ea seipone sa bohloeki:

Tube blank-inspection-peeling-inspection-heating-perforation-pickling-grinding-lubrication and air drying-welding head-cold drawing-solution treatment-pickling-pickling -ho bentša ka ntle-ho hlahloba-ho tšoaea-ho qeta ho paka sehlahisoa.

2. Ts'ebetso ea lipeipi tsa indasteri

Tube blank-inspection-peeling-hlahloba-heating-perforation-pickling-grinding-lubrication and air drying-welding head-cold drawing-solution treatment-pickling-pickling Passivation-inspection.

3. Ts'ebetso ea phallo ea phala e cheselitsoeng

Uncoiling-leveling-end ho kuta le welding-looper-forming-welding-ka hare le ka ntle lifaha ho tloswa-pele ho lokisoa-induction mocheso kalafo-sizing le straightening-eddy current test-cutting ——Hydraulic pressure inspection——Pickling——Tlhahlobo ea ho qetela —— Ho paka.

4. Ts'ebetso ea seamless square tube

Round steel-tube billet-inspection-heating-piercing-sizing-hot rolling-flat head-inspection-pickling-spherical annealing-cold drawing-forming-Qikou- -test

Q345A:C≤0.20,Mn ≤1.70,Si≤0.50,P≤0.035,S≤0.035;

Q345B:C≤0.20,Mn ≤1.70,Si≤0.50,P≤0.035,S≤0.035;

Q345C:C≤0.20,Mn ≤1.70,Si≤0.50,P≤0.030,S≤0.030,Al≥0.015;

Q345D:C≤0.18,Mn ≤1.70,Si≤0.50,P≤0.030,S≤0.025,Al≥0.015;

Q345E:C≤0.18,Mn ≤1.70,Si≤0.50,P≤0.025,S≤0.020,Al≥0.015;

Q345A, B, C, D, E Nb≤0.07,V≤0.15,Ti≤0.20,Cr≤0.30,N≤0.012,Mo≤0.10. 20#, Q235B

| Tafole ea lintlha tsa lipeipi tsa lisekoere tse teteaneng (mm) | Tafole ea tlhophiso ea lipeipi tse khutlonne tse teteaneng (mm) | ||

| 16~34×0.4–2.0 | 380~500×380~500×8.0~30.0 | 10~20×20~40×0.6–12.0 | 250~300×100~250×6~30.0 |

| 16~34×0.4–2.0 | Tlhaloso e 'ngoe ea redraw ke e latelang | 20×50×1.0–2.0 | 400×250×8–30.0 |

| 38×38×1.0–4.0 | 550×550×10.0–40.0 | 22~40×35~100×0.9~5.0 | 400~300×8~30.0 |

| 40~95×40~95×1.0~8.0 | 600~1000×600~1000×10.0~50.0 | 25×40×0.9–3.75 | 450~500×200~450×8~30.0 |

| 100×100×2.0–8.0 | 50×60×2.0–5.0 | Tlhaloso e 'ngoe ea redraw ke e latelang | |

| 120~350×120~350×4.0~30.0 | 50~200×60~150×2.0~12.0 | 600~1000×200~800×10~28.0 | |