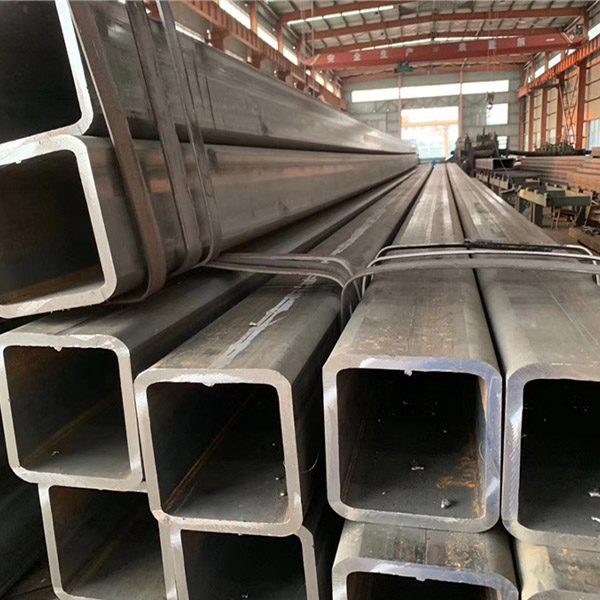

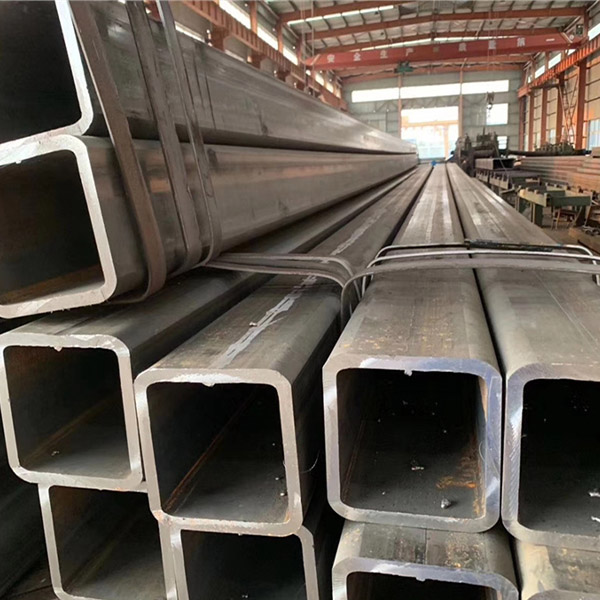

Seamless Square Tube

Tšebeliso: tube ea mokelikeli, tube ea boiler, tube ea mohaho

Alloyed kapa che: Ha e na alloyed

Sebopeho sa karolo: sekwere

Tube e khethehileng: tube e nang le marako a teteaneng

Boima: 140

Tekanyetso: ASTM

Bolelele: 12M, 6m, 6.4M, 1-12m

Setifikeiti: ISO9001

Mophato: Tšepe ea Carbon

Phekolo ea holim'a metsi: ho chesa ho pota

Mamello: ± 1%

Litšebeletso tsa ho sebetsa: ho cheselletsa, ho phunya, ho itšeha, ho koba

Keyword: hot rolled tube

Bonyane palo ea odara: 1 ton

Morero: Mohaho oa mohaho

Sebopeho: sekoere.

Rectangle. Ratoa

Mmala: mmala wa tlhaho

Packa: maemo a loketseng moea

Ts'ebetso ea ho paka: amohela tlhahiso e ikhethileng

E ipapisitse le boholo: boholo bo ikhethileng

Matla a Phepelo: Lithane tse 15,000 / lithane tsa lipeipi tsa tšepe tse lisekoere ka khoeli

Lintlha tsa ho paka: ho paka ka thepa e tloaelehileng kapa ho latela litlhoko tsa bareki.

Boema-kepe: China

Ha ho bapisoa le tšepe e tiileng joalo ka tšepe e chitja, peipi ea tšepe hangata e bobebe ha matla a ho kobeha le a torsion a tšoana. Ke mofuta oa tšepe e nang le likarolo tse fapaneng tsa moruo, e sebelisoang haholo ha ho etsoa likarolo tsa meralo le likarolo tsa mochini, joalo ka liphaephe tsa ho cheka oli, litšepe tsa phetisetso ea koloi, liraka tsa libaesekele le scaffolding ea tšepe e sebelisoang kahong. Tšebeliso ea lipeipi tsa tšepe ho etsa likarolo tse bōpehileng joaloka lesale e ka eketsa sekhahla sa tšebeliso ea thepa, ea nolofatsa mokhoa oa ho etsa thepa, le ho boloka lisebelisoa le ho sebetsa lihora tsa motho, tse kang li-ring ring, jack sleeve, joalo-joalo. E entsoe ka tšepe. liphaephe ka 2013. Liphaephe tsa tšepe le tsona ke thepa ea bohlokoa bakeng sa libetsa tse sa tšoaneng tse tloaelehileng le mechine ea sesole. Libarele tsa lithunya le libarele kaofela li entsoe ka liphaephe tsa tšepe. Liphaephe tsa tšepe li ka aroloa ka liphaephe tse chitja le liphaephe tse nang le sebōpeho se khethehileng ho ea ka libopeho tsa tsona tsa libaka tse tšekaletseng. Ka lebaka la boemo ba potoloho e lekanang, metsi a mangata a ka tsamaisoa ka tube e chitja. Ha karolo ea selikalikoe e tlas'a khatello ea mahlaseli a ka hare kapa a ka ntle, matla a batla a tšoana, 'me boholo ba liphaephe tsa tšepe ke liphaephe tse chitja.

1. Polasetiki

Plasticity e bolela bokhoni ba lisebelisoa tsa tšepe ho hlahisa deformation ea polasetiki (deformation e sa feleng) ntle le ho senyeha tlas'a mojaro.

2. Ho thatafala

Ho thatafala ke tekanyo ea boima ba thepa ea tšepe. Mokhoa o sebelisoang ka ho fetisisa oa ho lekanya boima ba tlhahiso ena ke mokhoa oa ho thatafala oa indentation, o sebelisang inndenter e itseng ea geometri ho hatella holim'a thepa ea tšepe e lokelang ho lekoa tlas'a mojaro o itseng, 'me boleng ba boima bo khethoa ho ea ka tekanyo. ea indentation.

Mekhoa e sebelisoang hangata e kenyelletsa Brinell hardness (HB), Rockwell hardness (HRA, HRB, HRC) le Vickers hardness (HV).

3. Mokhathala

Matla, polasetiki le ho thatafala ke matšoao a lisebelisoa tsa tšepe tse tlas'a mojaro o tsitsitseng. Ebile, likarolo tse ngata tsa mochini li sebetsa tlasa meroalo ea cyclic, tlasa boemo bona likarolo li tla khathala. Ho boetse hoa hlokahala lipeipi tsa tšepe tse nang le sebōpeho se khethehileng tse nang le libopeho tse ling tse fapaneng.

Peipi ea tšepe e cheselitsoeng bakeng sa lipalangoang tsa mokelikeli o tlase (GB/T3092-1993) e boetse e bitsoa phala e akaretsang e cheselitsoeng, e tsejoang ka hore ke clarinet. Ke phala ea tšepe e cheselitsoeng e sebelisetsoang ho tsamaisa metsi, khase, moea, oli le mouoane o futhumatsang le maro a mang ka kakaretso a nang le khatello e tlase le merero e meng. Botenya ba lerako la liphaephe tsa tšepe bo arotsoe ka liphaephe tse tloaelehileng tsa tšepe le liphaephe tsa tšepe tse teteaneng; liforomo tsa ho qetela tsa khokahanyo li arotsoe ka liphaephe tsa tšepe tse se nang khoele (liphaephe tse boreleli) le liphaephe tsa tšepe tse entsoeng ka khoele. Tlhaloso ea phala ea tšepe e hlalosoa ka bophara ba lebitso (mm), e leng tekanyo e hakanyetsoang ea bophara bo ka hare. Ke tloaelo ho hlalosa ka lisenthimithara, joalo ka 11/2. Lipeipi tsa tšepe tse cheselitsoeng bakeng sa lipalangoang tsa mokelikeli o tlase ha li sebelisoe ka kotloloho feela bakeng sa lipalangoang tsa mokelikeli, empa hape li sebelisoa e le liphaephe tsa pele tsa lipeipi tsa tšepe tse entsoeng ka masenke bakeng sa lipalangoang tsa mokelikeli o tlase.

Peipi ea tšepe e entsoeng ka galvanized bakeng sa lipalangoang tsa mokelikeli o tlaase (GB/T3091-1993) e boetse e bitsoa phala ea tšepe e entsoeng ka galvanized, e tsejoang ka hore ke phala e tšoeu. Ke peipi ea tšepe e cheselitsoeng ka sebopi e cheselitsoeng (sebopi se cheselitsoeng kapa se cheselitsoeng ka motlakase) se sebelisetsoang ho tsamaisa metsi, khase, oli ea moea, mouoane o futhumatsang, metsi a futhumetseng le maro a mang a tlase a khatello kapa merero e meng. Botenya ba lerako la phala ea tšepe bo arotsoe ka phala e tloaelehileng ea galvanized tšepe le phala e teteaneng ea tšepe; mofuta oa ho qetela oa khokahano o arotsoe ka phala ea tšepe e sa kenngoeng ka likhoele le phala ea tšepe e entsoeng ka likhoele.

Casing e tloaelehileng ea tšepe ea carbon steel (GB3640-88) ke phala ea tšepe e sebelisetsoang ho sireletsa lithapo mererong ea ho kenya motlakase joalo ka kaho ea indasteri le ea sechaba le ho kenya mechini le lisebelisoa.

Seam seam electric welded steel pipe (YB242-63) ke phala ea tšepe eo seam sa eona sa weld se bapileng le tataiso ea longitudinal ea phala ea tšepe. Hangata e arotsoe ka phala ea tšepe ea metric e entsoeng ka tšepe, phala ea motlakase e tšesaane e nang le marako, phala ea oli e pholileng ea transformer joalo-joalo.

Spiral seam submerged arc welded steel pipe (SY5036-83) bakeng sa sepalangoang sa mokelikeli o nang le khatello ke lesela le chesang le kolobisitsoeng joaloka tube e se nang letho, e entsoeng ka moea ka mocheso o tloaelehileng 'me e chesetsoa ka mahlakoreng a mabeli a koahetsoeng ke metsi. E sebelisoa bakeng sa seam sa spiral sa lipalangoang tsa mokelikeli o nang le khatello. Pipe ea tšepe. Pipe ea tšepe e na le matla a matla a ho jara khatello le ts'ebetso e ntle ea welding. Kamora ho hlahlojoa le liteko tse fapaneng tse tiileng tsa mahlale, e bolokehile ebile e ka tšeptjoa ho e sebelisa. Pipe ea tšepe e na le bophara bo boholo, ts'ebetso e phahameng ea phetisetso, 'me e ka boloka matsete a ho beha liphaephe. E sebelisoa haholo liphaepheng tsa ho tsamaisa oli le khase ea tlhaho.

| Tshebeletso ya tshebetso | Ho kobeha, ho tjheseletsa, ho theola |

| Ho tlotsoa ka oli kapa ho tlotsoa | Ha ho mafura |

| Lebitso la sehlahisoa | Pipe ea polasetiki e koahetsoeng ka hare |

| Moq | 1 ton |

| Mantsoe a sehlooho | E kentsoeng ka phala ea tšepe e sa hloekang |

| Bokaholimo | Kopo ea bareki |

| Sebopeho | Sekwere tube |

| Nako ea thomello | Ka hare ho matsatsi a 7-15 |

| Standard | Gb 5310-1995 |

Mokhoa oa ho hokahanya lipeipi tsa tšepe tse entsoeng ka galvanized: khoele, tse cheselitsoeng.

Khokahano ea li-groove

(1) Ho petsoha ha roll groove weld

1. Rerelletsa lerako le ka hare ho tjheseletsa likhopo tsa karolo ea khatello ea groove ea nozzle ho fokotsa ho hanyetsa ha groove e bilikang.

2, Fetola axis ea phala ea tšepe le lisebelisoa tsa ho roala, 'me u hloka hore phala ea tšepe le lisebelisoa tsa ho roala li be boemong bo lekanang.

3. Fetola lebelo la ho hatella groove, 'me nako ea ho etsa groove e ke ke ea feta tekano, sebelisa matla ka mokhoa o ts'oanang le butle.

(2) Ho robeha ha phala ea tšepe ea groove

1. Rerelletsa lerako le ka hare ho tjheseletsa likhopo tsa karolo ea groove ea khatello ea molomo oa phala ho fokotsa khanyetso ea groove.

2, Lokisa axis ea phala ea tšepe le lisebelisoa tsa ho roala, tse hlokang hore pipe ea tšepe le lisebelisoa tsa ho roala li be boemong.

3. Fetola lebelo la ho hatella, lebelo la ho hatella le ke ke la feta stipulation, sebelisa matla ka ho lekana le butle.

4. Sheba bophara le mohlala oa mochine o tšehetsang le khatello ea khatello ea thepa ea li-rolling groove, 'me u hlahlobe hore na ho na le ho se lumellane ka boholo ba li-roller tse peli, tse ka bakang ho tšoaroa.

5. Sebelisa vernier caliper ho hlahloba hore na groove ea pipe ea tšepe e hlalositsoe.

(3) The groove e entsoeng ke mochine oa rolling groove e lokela ho finyella litlhoko tse latelang

1, Bokaholimo ba phala e qetellang ho ea karolong ea groove e lokela ho ba boreleli ebile e se na ho se lekane le matšoao a moqolo.

2, Bohareng ba groove bo lokela ho ba bo tebileng le lerako la phala, bophara le botebo ba groove li lokela ho finyella litlhoko, 'me u hlahlobe hore na mofuta oa karolo ea clamp o nepahetse.

3. Kenya mafura holim'a selikalikoe sa ho tiisa rabara 'me u hlahlobe hore na reng ea ho tiisa rabara e senyehile. Setlolo ha sea lokela ho ba setlolo sa oli.

Khokahano e cheselitsoeng

1. Molomo oa phala ea phala ea tšepe ea galvanized ha o otlolohile 'me ho na le bothata ka molomo oa oblique oa pipe ea tšepe ka mor'a ho phunya. Ho kgothaletswa ho khaola hlooho ea pipe ka nako e khutšoanyane pele ho sebetsa.

2, Ka mor'a hore li-nozzles tsa lipeipi tsa tšepe li kopanngoe, li-nozzles tse peli ha li kopane ka thata, e leng se etsang hore ho be le botenya bo sa lekaneng ba lenonyeletso le cheselitsoeng; 'me phala e na le elliptical ka lebaka la mabaka a eona kapa maqhubu a lipalangoang. Ho khothalletsoa ho khaola hlooho ea pipe ka nako e khutšoanyane. Tshebetso hape.

3. Ka mor'a hore ho koetsoe liphaephe tsa tšepe tse entsoeng ka masenke, maqhetsoana a hlaha likonong:

4. Ka lebaka la mabaka a botekgeniki nakong tjheseletsa.

5. Ho na le maqhutsu a zinki ka nozzle, a ka bakang mathata a ho cheselletsa le mahlaseli. Haeba maqhutsu a zinki a le maholo haholo le liphaephe tse ngata haholo, li-nodule tse bonolo tsa zinki li lokela ho tlosoa.

Khokahano ea mohala

1, Buckle e nang le khoele: Hupu ea lipeipi le lesela le khoele li ke ke tsa hokahanngoa ka botlalo, tsa lokolla, tsa khaola karolo e sa reroang, ebe o kenya khoele hape.

2. Khoele ea phala ea tšepe le khoele ea hoop ea pipe ha e lumellane ebile e ke ke ea kopanngoa. Hoop ea lipeipi e lokela ho nkeloa sebaka kapa thepa e lokisoe le ho khoasoa hape.

3. Phatlalatso e sieo ka mor'a hore phala ea tšepe e kenngoe: Lekanya hore na botenya ba lebota la phala ea tšepe bo ka finyella litlhoko tse tloaelehileng tsa phala e entsoeng ka khoele.