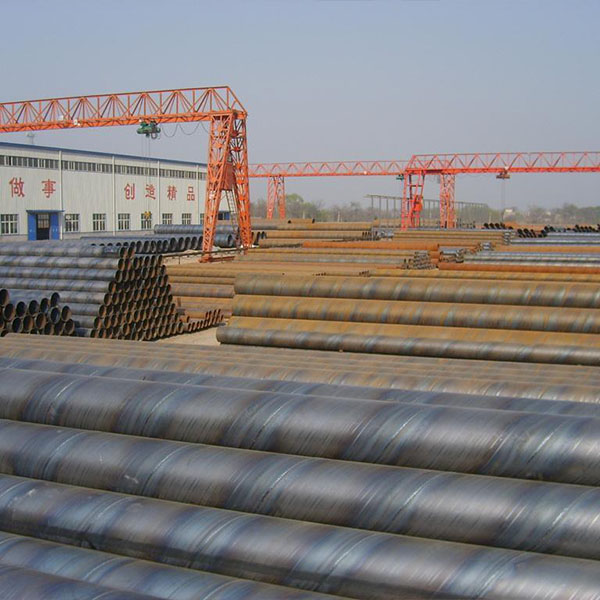

Q235B Spiral Tube

Maemo a tloaelehileng a sebelisoang bakeng sa liphaephe tsa tšepe tsa spiral hangata li arotsoe ka: SY/T5037-2000 (Tekanyetso ea Lekala, eo hape e bitsoang spiral seam submerged arc welded steel pipe bakeng sa liphaephe tse tloaelehileng tsa lipalangoang tsa mokelikeli), GB/T9711.1-1997 (Tekanyetso ea Naha, e boetse e bitsoa phala ea tšepe ea phepelo ea oli le khase Karolo ea pele ea maemo a phano ea tekheniki: Pipe ea tšepe ea Kereiti ea A (GB/T9711.2 Grade Pipe ea tšepe ea B e hlokahala ka thata), API-5L (Setsi sa Amerika sa Petroleum, seo hape se bitsoang pipeline tšepe pipe; e arotsoe ka lihlopha tse peli: PSL1 le PSL2), SY/T5040-92 (Spiral submerged arc welded steel pipe for qubu).

(1) Lisebelisoa ke li-coil tsa tšepe tse hlobolang, lithapo tsa li-welding le li-fluxes. Ho hlokahala tlhahlobo e matla ea 'mele le ea lik'hemik'hale pele ho matsete.

(2) Butt e kopane ea hlooho le mohatla, e sebelisa terata e le 'ngoe kapa terata e le 'ngoe e kenngoeng ka metsing, ka mor'a hore e kene ka har'a phala ea tšepe, tjheseletsa e kentsoeng ka metsing e sebelisoa bakeng sa ho lokisa welding.

(3) Pele o etsoa, moqhaka o etsoa ho lekanngoa, ho fokotsa moeli, ho betla moeli, ho hloekisa holim'a metsi le ho tsamaisa, le phekolo ea pele ho koba.

4

(5) Amohela taolo ea kantle kapa ho theha lethathamo la taolo ea kahare.

(6) Sesebelisoa sa ho laola lekhalo la weld se sebelisoa ho etsa bonnete ba hore lekhalo la weld le kopana le litlhoko tsa ho tjheseletsa, le bophara ba phala, palo ea ho se lumellane le lekhalo la weld li laoloa ka thata.

7

(8) Li-welds li hlahlojoa ke sesebelisoa sa marang-rang se tsoelang pele sa ultrasonic, se tiisang 100% tlhahlobo e sa senyeheng ea li-spiral welds.

(9) Sebelisa mochine o sehang plasma ea moea ho khaola phala ea tšepe ka likotoana ka bomong.

(10) Ka mor'a ho seha liphaepheng tsa tšepe tse le 'ngoe, liphaephe tse tharo tsa pele tsa tšepe tsa sehlopha ka seng li tla kena tsamaisong e tiileng ea pele ea tlhahlobo ho netefatsa hore mokhoa oa ho etsa lipeipi o tšoaneleha pele o kenngoa ka molao tlhahiso.

(11) Likarolo tse nang le matšoao a tsoelang pele a ho lemoha liphoso tsa sonic ho li-welds li etsoa tlhahlobo ea ultrasonic le X-ray hape.

(12) Liphaephe tseo moroko oa tšupiso oa tšepe o tjheseletsang le manonyeletso a bōpehileng joaloka D a kopanang le litšepe tse bululelang, kaofela li hlahlojoa ka thelevishene ea X-ray kapa ho nkuoa filimi.

(13) Pipe e 'ngoe le e' ngoe ea tšepe e kena tekong ea khatello ea hydrostatic, 'me khatello e amohela tiiso ea radial. Khatello ea teko le nako li laoloa ka thata ke sesebelisoa sa ho lemoha phala ea tšepe ea hydraulic microcomputer. Litekanyetso tsa liteko li hatisoa le ho rekotoa ka bo eona.

(14) Pipe end machining, e le hore verticality ea sefahleho qetellong, angle bevel le bohale obtuse ka laoloa ka nepo.

Spiral seam submerged arc welded steel pipe (SY5036-83) bakeng sa ho tsamaisa mokelikeli o nang le khatello e sebelisoa haholo bakeng sa liphaephe tsa ho tsamaisa oli le khase ea tlhaho; spiral seam high-frequency welded steel pipe (SY5038-83) bakeng sa sepalangoang sa mokelikeli o nang le khatello, ho sebelisoa mokhoa oa ho tjheseletsa oa maqhubu a phahameng-frequency lap Welded, spiral seam high-frequency welded steel pipe bakeng sa lipalangoang tse nang le khatello ea metsi. Pipe ea tšepe e na le matla a matla a ho jara khatello le polasetiki e ntle, e loketseng ho cheselletsa le ho sebetsa. Ka kakaretso, seam spiral seam submered arc welded steel pipe (SY5037-83) bakeng sa lipalangoang tsa mokelikeli o tlase o entsoe ka tjheseletsa e nang le mahlakore a mabeli a ka tlas'a metsi kapa tjheseletsa e lehlakoreng le le leng bakeng sa metsi, phala ea tšepe e kentsoeng ka tlas'a metsi bakeng sa ho fetisa mokelikeli o tlase oa khatello e tlase. joalo ka khase, moea le mouoane