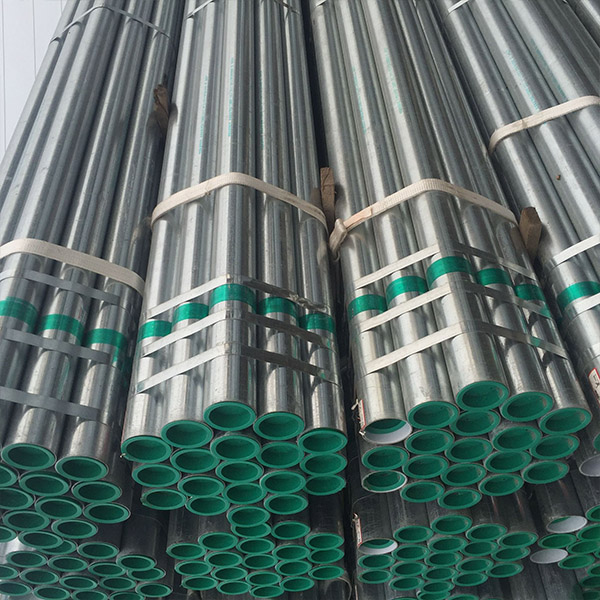

Mocheso oa Dip Galvanized Steel

Botenya ba lebota ka lebitso (mm): 2.0, 2.5, 2.8, 3.2, 3.5, 3.8, 4.0, 4.5.

Liparamente tsa coefficient (c): 1.064, 1.051, 1.045, 1.040, 1.036, 1.034, 1.032, 1.028.

Tlhokomeliso: Thepa ea mochine ea tšepe ke index ea bohlokoa ho netefatsa ts'ebetso ea ho qetela ea ts'ebeliso (thepa ea mechine) ea tšepe, 'me e itšetlehile ka lik'hemik'hale tsa tšepe le tsamaiso ea mocheso oa mocheso. Tekanyetso ea lipeipi tsa tšepe, ho latela litlhoko tse fapaneng tsa kopo, thepa ea ho tsitsa (matla a thata, matla a tlhahiso kapa ntlha ea tlhahiso, elongation),li-index tsa hardness le toughness li hlalositsoe, hammoho le thepa ea mocheso o phahameng le o tlase o hlokoang ke basebelisi.

Limaraka tsa tšepe: Q215A; Q215B; Q235A; Q235B.

Boleng ba khatello ea teko / Mpa: D10.2-168.3mm ke 3Mpa; D177.8-323.9mm ke 5Mpa

Litekanyetso tsa naha le boholo ba lipeipi tse entsoeng ka masenke

GB/T3091-2015 phala ea tšepe e cheselitsoeng bakeng sa lipalangoang tsa mokelikeli o tlase oa khatello

GB/T13793-2016 Longitudinal motlakase welded tšepe pipe

GB/T21835-2008 welded tšepe phala boholo le boima ba yuniti bolelele

Phallo ea ts'ebetso ke:nkho e ntšo ea alkaline ea ho hlatsoa-metsi a hlatsoa-pickling-metsi rinsing-inela aid-drying-hot dip galvanizing-external blowing-internal blowing-air-pholisa-metsi pholiso -Pasivation-metsi rinsing-inspection-weighing-storage.

Lipeipi tse atisang ho boleloa ka masenke, lipeipi tsa masenke li sebelisetsoa khase, 'me mofuta oa lipeipi tsa tšepe tse sebelisetsoang ho futhumatsa le tsona ke lipeipi tsa masenke. Liphaephe tse nang le galvanized li sebelisoa e le lipeipi tsa metsi. Ka mor'a lilemo tse 'maloa tsa tšebeliso, mafome a mangata le litšila li hlahisoa ka har'a liphaephe,' me metsi a mosehla a phallang ha a silafatse feela thepa ea bohloeki , 'Me e kopantsoe le libaktheria tse hlahisang leboteng le ka hare le sa lekaneng,' me ho senya ho baka. boleng bo phahameng ba litšepe tse boima ka metsing, tse behang bophelo bo botle ba 'mele oa motho kotsing.

Mokhoa oa ho hokahanya lipeipi tsa tšepe tse entsoeng ka galvanized: khoele, tse cheselitsoeng.

Khokahano ea li-groove

(1) Ho petsoha ha roll groove weld

1. Rerelletsa lerako le ka hare ho tjheseletsa likhopo tsa karolo ea khatello ea groove ea nozzle ho fokotsa ho hanyetsa ha groove e bilikang.

2, Fetola axis ea phala ea tšepe le lisebelisoa tsa ho roala, 'me u hloka hore phala ea tšepe le lisebelisoa tsa ho roala li be boemong bo lekanang.

3. Fetola lebelo la ho hatella groove, 'me nako ea ho etsa groove e ke ke ea feta tekano, sebelisa matla ka mokhoa o ts'oanang le butle.

(2) Ho robeha ha phala ea tšepe ea groove

1. Rerelletsa lerako le ka hare ho tjheseletsa likhopo tsa karolo ea groove ea khatello ea molomo oa phala ho fokotsa khanyetso ea groove.

2, Lokisa axis ea phala ea tšepe le lisebelisoa tsa ho roala, tse hlokang hore pipe ea tšepe le lisebelisoa tsa ho roala li be boemong.

3. Fetola lebelo la ho hatella, lebelo la ho hatella le ke ke la feta stipulation, sebelisa matla ka ho lekana le butle.

4. Sheba bophara le mohlala oa mochine o tšehetsang le khatello ea khatello ea thepa ea li-rolling groove, 'me u hlahlobe hore na ho na le ho se lumellane ka boholo ba li-roller tse peli, tse ka bakang ho tšoaroa.

5. Sebelisa vernier caliper ho hlahloba hore na groove ea pipe ea tšepe e hlalositsoe.

(3) The groove e entsoeng ke mochine oa rolling groove e lokela ho finyella litlhoko tse latelang

1, Bokaholimo ba phala e qetellang ho ea karolong ea groove e lokela ho ba boreleli ebile e se na ho se lekane le matšoao a moqolo.

2, Bohareng ba groove bo lokela ho ba bo tebileng le lerako la phala, bophara le botebo ba groove li lokela ho finyella litlhoko, 'me u hlahlobe hore na mofuta oa karolo ea clamp o nepahetse.

3. Kenya mafura holim'a selikalikoe sa ho tiisa rabara 'me u hlahlobe hore na reng ea ho tiisa rabara e senyehile. Setlolo ha sea lokela ho ba setlolo sa oli.

Khokahano e cheselitsoeng

1. Molomo oa phala ea phala ea tšepe ea galvanized ha o otlolohile 'me ho na le bothata ka molomo oa oblique oa pipe ea tšepe ka mor'a ho phunya. Ho kgothaletswa ho khaola hlooho ea pipe ka nako e khutšoanyane pele ho sebetsa.

2, Ka mor'a hore li-nozzles tsa lipeipi tsa tšepe li kopanngoe, li-nozzles tse peli ha li kopane ka thata, e leng se etsang hore ho be le botenya bo sa lekaneng ba lenonyeletso le cheselitsoeng; 'me phala e na le elliptical ka lebaka la mabaka a eona kapa maqhubu a lipalangoang. Ho khothalletsoa ho khaola hlooho ea pipe ka nako e khutšoanyane. Tshebetso hape.

3. Ka mor'a hore ho koetsoe liphaephe tsa tšepe tse entsoeng ka masenke, maqhetsoana a hlaha likonong:

4. Ka lebaka la mabaka a botekgeniki nakong tjheseletsa.

5. Ho na le maqhutsu a zinki ka nozzle, a ka bakang mathata a ho cheselletsa le mahlaseli. Haeba maqhutsu a zinki a le maholo haholo le liphaephe tse ngata haholo, li-nodule tse bonolo tsa zinki li lokela ho tlosoa.

Khokahano ea mohala

1, Buckle e nang le khoele: Hupu ea lipeipi le lesela le khoele li ke ke tsa hokahanngoa ka botlalo, tsa lokolla, tsa khaola karolo e sa reroang, ebe o kenya khoele hape.

2. Khoele ea phala ea tšepe le khoele ea hoop ea pipe ha e lumellane ebile e ke ke ea kopanngoa. Hoop ea lipeipi e lokela ho nkeloa sebaka kapa thepa e lokisoe le ho khoasoa hape.

3. Phatlalatso e sieo ka mor'a hore phala ea tšepe e kenngoe: Lekanya hore na botenya ba lebota la phala ea tšepe bo ka finyella litlhoko tse tloaelehileng tsa phala e entsoeng ka khoele.