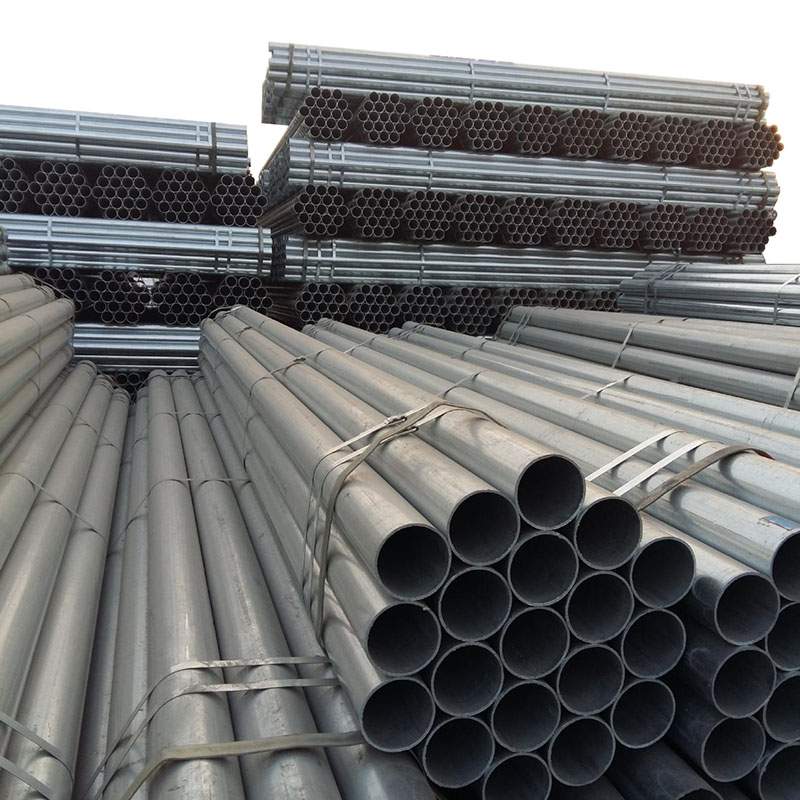

Pipe ea Tšepe e Kolohileng e Kolohileng

| Lebitso | Tšepe e entsoeng ka galvanized | Intrinsic | Tšepe |

| Karolelano | Pipe ea tšepe e batang, peipi e chesang ea masenke | Sebaka sa kopo | Kaho, mechini, morafo oa mashala, indasteri ea lik'hemik'hale, matla a motlakase, koloi ea terene, indasteri ea likoloi, tsela e kholo, borokho, setshelo, lisebelisoa tsa lipapali, mechini ea temo, metjhini ea petroleum, metjhini ea ho etsa lipatlisiso Eketsa. |

| Bolelele | 6m bolelele bo tsitsitseng | ||

| Botenya ba lebota ka lebitso (mm) | 2.0, 2.5, 2.8, 3.2, 3.5, 3.8, 4.0, 4.5 |

1.Matla a ho tiea (σb): Matla a maholo (Fb) ao mohlala o bang le tsitsipano ha o huloa, o arotsoe ke khatello ea maikutlo (σ) e fumanoang sebakeng sa pele sa sefapano (So) sa mohlala, se bitsoa tensile strength ( σ) σb), ka N/mm2 (MPa). E emela boholo ba matla a thepa ea tšepe ho hanyetsa tšenyo tlas'a tsitsipano. Moo: Fb - matla a mangata ao mohlala o mamellang ha o huloa, N (Newton); Kahoo - sebaka sa pele sa sefapano sa mohlala, mm2.

2.tlhahiso ea lihlahisoa (σs): lisebelisoa tsa tšepe tse nang le phenomenon ea lihlahisoa, khatello ea kelello ha mohlala o ka tsoela pele ho lelefatsa ntle le ho eketseha ha matla (ho lula o le teng) nakong ea ts'ebetso ea ho otlolla, e bitsoang ntlha ea lihlahisoa. Haeba matla a fokotseha, lintlha tsa lihlahisoa tse holimo le tse tlaase li lokela ho khetholloa. Karolo ea ntlha ea lihlahisoa ke N/mm2 (MPa). Ntho e ka holimo ea lihlahisoa (σsu): khatello e phahameng ea khatello pele mohlala o hlahisa 'me matla a qala ho fokotseha; Ntho e ka tlaase ea lihlahisoa (σsl): khatello e fokolang karolong ea ho fana ha phello ea pele ea nakoana e sa baloe. Moo: Fs - tlhahiso ea matla (kamehla) ea mohlala ka tsitsipano, N (Newton) Kahoo - sebaka sa pele sa karolo ea setšoantšo, mm2.

3.Elongation after break: (σ) Tekong ea tensile, peresente ea keketseho ea bolelele ba mohlala ka mor'a ho hula sekala sa eona ho ea bolelele ba sekala sa pele se bitsoa elongation. E hlalositsoe ka σ, yuniti ke %. Moo: L1 - bolelele ba mohlala ka mor'a hore mohlala o huloe, mm; L0 - bolelele ba molumo oa mantlha oa mohlala, mm.

4.Fractional shrinkage: (ψ) Tekong ea tensile, ho honyela ho hoholo ha karolo ea karolo ea sefapano ho honyeha ha eona ka mor'a hore mohlala o huloe e le peresente ea sebaka sa pele sa sefapano se bitsoang "fractional shrinkage". E hlalositsoe joalo ka ψ, ka %. Moo: S0 - sebaka sa pele sa sefapano sa mohlala, mm2; S1 - sebaka se fokolang sa karolo e ka holimo ho shrinkage ka mor'a hore mohlala o tlosoe, mm2.

5.Hardness index/ Ketso ya tshepe: bokgoni ba tshepe ho hanela ho kenyeletsoa hoa ntho e thata bokahodimong, ho bitswang boima. Ho ipapisitsoe le mokhoa oa teko le boholo ba ts'ebeliso, boima bo ka aroloa ka boima ba Brinell, Rockwell hardness, Vickers hardness, Shore hardness, microhardness le boima bo phahameng ba mocheso. Bakeng sa tube ka kakaretso e sebelisoa Brinell, Rockwell, Vickers hardness tharo.

Brinell hardness (HB): U sebelisa bolo ea tšepe kapa ea carbide ea bophara bo itseng, tobetsa matla a teko a boletsoeng (F) ka holim'a mohlala, tlosa matla a teko ka mor'a nako e behiloeng, 'me u lekanye bophara ba ho indentation (L) hodima bokahodimo ba mohlala. Boleng ba Brinell hardness ke quotient e fumanoeng ka ho arola matla a teko ka sebaka sa spherical sa indentation. E hlahiswa joalo ka HBS (bolo ea tšepe) ka N/mm2 (MPa).

Liphaephe tsa tšepe tse chesang-dip li sebelisoa haholo ho haha, mechine, merafo ea mashala, indasteri ea lik'hemik'hale, matla a motlakase, likoloi tsa terene, indasteri ea likoloi, litsela tse kholo, marokho, lijana, lisebelisoa tsa lipapali, mechine ea temo, mechine ea peterole, mechine ea ho etsa lipatlisiso le liindasteri tse ling tsa tlhahiso. .

Pipe ea tšepe e entsoeng ka galvanized ke phala ea tšepe e cheselitsoeng e nang le metsi a chesang kapa a electro galvanized surface. Galvanization e ka eketsa ho hanyetsa ha kutu ea liphaephe tsa tšepe le ho lelefatsa bophelo ba tšebeletso. Peipi ea tšepe e nang le matlapa e na le mefuta e mengata ea ts'ebeliso, ntle le ho sebelisoa e le phaephe bakeng sa maro a tloaelehileng a khatello e tlase joalo ka metsi, khase le oli, hape e sebelisoa joalo ka peipi ea seliba sa oli le phaephe ea oli indastering ea peterole, haholoholo masimo a oli a leoatleng, joalo ka sefuthumatsi sa oli, se futhumatsang oli, se futhumatsang mashala le mochini o hlatsoang oli bakeng sa lisebelisoa tsa ho pheha lik'hemik'hale, hape e le phala ea ts'ehetso bakeng sa qubu ea lipeipi tsa trestle le likoting tsa merafo, etc.

Peipi ea metsi, peipi ea oli, peipi ea scaffolding, terata ea litsela tse kholo, sekoaelo sa shed, joalo-joalo.

| Bophara ba ka hare ka lebitso | Intshi | Bophara ba ka ntle mm | Botenya ba lebota mm | Botenya bo fokolang ba lebota mm | Boima ba mithara kg | Boima ba motso lik'hilograma | Boima ba mithara kg | Boima ba motso lik'hilograma |

| DN15 Peipi e entsoeng ka galvanized | 1/2 | 21.3 | 2.8 | 2.45 | 1.28 | 7.68 | 1.357 | 8.14 |

| DN20 Peipi e entsoeng ka galvanized | 3/4 | 26.9 | 2.8 | 2.45 | 1.66 | 9.96 | 1.76 | 10.56 |

| DN25 Peipi e entsoeng ka galvanized | 1 | 33.7 | 3.2 | 2.8 | 2.41 | 14.46 | 2.554 | 15.32 |

| DN32 Peipi e entsoeng ka galvanized | 1.25 | 42.4 | 3.5 | 3.06 | 3.36 | 20.16 | 3.56 | 21.36 |

| DN40 Peipi e entsoeng ka galvanized | 1.5 | 48.3 | 3.5 | 3.06 | 3.87 | 23.22 | 4.10 | 24.60 |

| DN50 Peipi e entsoeng ka galvanized | 2 | 60.3 | 3.8 | 3.325 | 5.29 | 31.74 | 5.607 | 33.64 |

| Pipe ea galvanized ea DN65 | 2.5 | 76.1 | 4.0 | 3.5 | 7.11 | 42.66 | 7.536 | 45.21 |

| DN80 Pipe e entsoeng ka masenke | 3 | 88.9 | 4.0 | . | 8.38 | 50.28 | 8.88 | 53.28 |

| DN100 Peipi e entsoeng ka galvanized | 4 | 114.3 | 4.0 | . | 10.88 | 65.28 | 11.53 | 69.18 |